STATE AND WAYS OF DEVELOPMENT OF AQUACULTURE IN

THE RUSSIAN FEDERATION

THE RUSSIAN FEDERATION

The Russian Federation Ministry of Agriculture

The Federal Agency for Fishery

FSBEI HE «Kaliningrad State Technical University»

FSBEI HE «Saratov State Agrarian University Named after N.I. Vavilov»

The Federal Agency for Fishery

FSBEI HE «Kaliningrad State Technical University»

FSBEI HE «Saratov State Agrarian University Named after N.I. Vavilov»

V NATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE

Editorial Board:

Vasiliev A. A., Kuznetsov M. Yu., Rudneva O. N., Sivokhina L. A.

© FSBEI HE Saratov SAU, 2020

Vasiliev A. A., Kuznetsov M. Yu., Rudneva O. N., Sivokhina L. A.

© FSBEI HE Saratov SAU, 2020

IMPROVEMENT OF THE HIDROCHEMICAL COMPOSITION OF WATER IN THE CLOSED WATER SUPPLY SYSTEM (CWSS) WITH THE IMPLEMENTATION OF A TWO-STAGE MECHANICAL DRUM FILTER

Material of the V National scientific and practical conference

"State and ways of development of aquaculture in the Russian Federation"

The authors of the published material are responsible for incorrect borrowing, selection and accuracy of the facts, citations, statistics and materials that are not subject to open publication. The material is published in the author's editorial office.

"State and ways of development of aquaculture in the Russian Federation"

The authors of the published material are responsible for incorrect borrowing, selection and accuracy of the facts, citations, statistics and materials that are not subject to open publication. The material is published in the author's editorial office.

A.N. BRITOV, A.A. VASILIEV

FSBEI HE «Saratov State Agrarian University Named after N.I. Vavilov»

UBC: 636.5.034:636. 087.7

FSBEI HE «Saratov State Agrarian University Named after N.I. Vavilov»

UBC: 636.5.034:636. 087.7

Abstract. The article presents the results of scientific and economic experience, indicators of residual mechanical contamination of water composition in the closed water supply system (CWSS) when implementing a two-stage mechanical drum filter, using microgrids of various cross-sections, namely, 40, 57, 90 microns.

The introduction of two stages of purification allows to increase the efficiency of filtration of recycled water, separating different sized waste fractions at each stage, preventing the "grinding" of larger fish waste, screening out at the first stage of purification.

Keywords: Mechanical drum filter, Closed water supply setting, Filter element, Microgrid, CWSS.

The Russian market for commercial fish production in closed water supply system (CWSS) settings has been characterized by high growth rates in recent years. Despite the period of economic instability caused by the crisis in the world economy, growth rates have remained positive and relatively high. The structure of the market and its development prospects allow us to conclude that the situation is favourable for the implementation of the projects in the sphere of industrial fish farming. In Russia, aquaculture production increased from 90 400 tonnes in 2001 to 173 840 tonnes in 2016. The share of aquaculture in the total production in the Russian Federation is about 4% [10, 11].

The main promising area for the development of the industry is the year-round commercial production of fish in CWSS [3, 5, 6, 8]. High-quality treatment of recycled water in the ultrasound plant will minimize the risks of the entire complex. The efficiency and high operational characteristics of the equipment used by the CWSS is the basis for the reliable functioning of the entire life support system for hydrobionts [2, 4, 7].

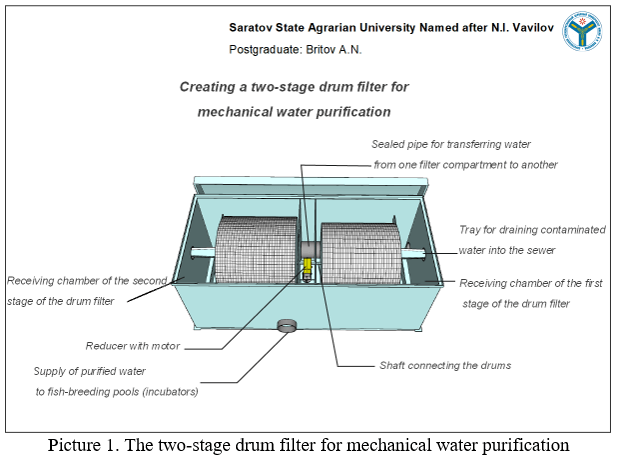

To conduct a scientific and economic experiment on the basis of "Fish House" LLC, Engels, Saratov region, we designed a two-stage mechanical drum filter (Fig. 1) and installed it in the CWSS where trout was raised. The described two-stage drum filter is created in the form of an industrial design and is approved in production. The novelty of the above device is confirmed by the RF patent for utility model № 195933 [1, 9].

The introduction of two stages of purification allows to increase the efficiency of filtration of recycled water, separating different sized waste fractions at each stage, preventing the "grinding" of larger fish waste, screening out at the first stage of purification.

Keywords: Mechanical drum filter, Closed water supply setting, Filter element, Microgrid, CWSS.

The Russian market for commercial fish production in closed water supply system (CWSS) settings has been characterized by high growth rates in recent years. Despite the period of economic instability caused by the crisis in the world economy, growth rates have remained positive and relatively high. The structure of the market and its development prospects allow us to conclude that the situation is favourable for the implementation of the projects in the sphere of industrial fish farming. In Russia, aquaculture production increased from 90 400 tonnes in 2001 to 173 840 tonnes in 2016. The share of aquaculture in the total production in the Russian Federation is about 4% [10, 11].

The main promising area for the development of the industry is the year-round commercial production of fish in CWSS [3, 5, 6, 8]. High-quality treatment of recycled water in the ultrasound plant will minimize the risks of the entire complex. The efficiency and high operational characteristics of the equipment used by the CWSS is the basis for the reliable functioning of the entire life support system for hydrobionts [2, 4, 7].

To conduct a scientific and economic experiment on the basis of "Fish House" LLC, Engels, Saratov region, we designed a two-stage mechanical drum filter (Fig. 1) and installed it in the CWSS where trout was raised. The described two-stage drum filter is created in the form of an industrial design and is approved in production. The novelty of the above device is confirmed by the RF patent for utility model № 195933 [1, 9].

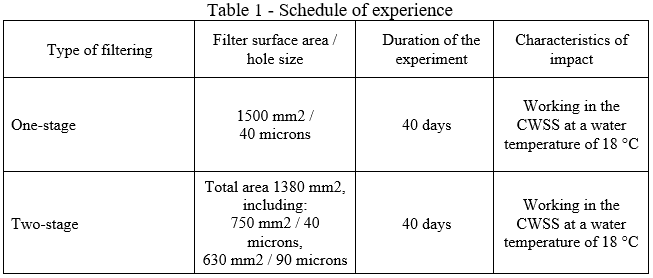

During the first stage of the experiment, we installed in the CWSS a single-stage drum filter for mechanical water purification with a cell size of 40 microns with a water volume of 75 m3 in fish-breeding pools (Table 1). The duration of the experiment was 40 days. The operation of the CWSS was carried out in the normal mode of fish feeding, cleaning of deposits from pipelines, pits and pools.

In the second stage of the experiment, we replaced a one-stage mechanical drum filter to a two-stage mechanical drum filter. The first stage of a mechanical drum filter with an area of 630 mm² and a cell size of 90 microns. The second stage of a mechanical drum filter with a mesh area of 750 microns and a cell size of 40 microns.

During the experiment, the multiplicity and level of feeding, as well as the fish biomass, were approximately at the same level. In feeding trout, granulated feed from one manufacturer and one batch was used. The color of the water did not have significant differences.

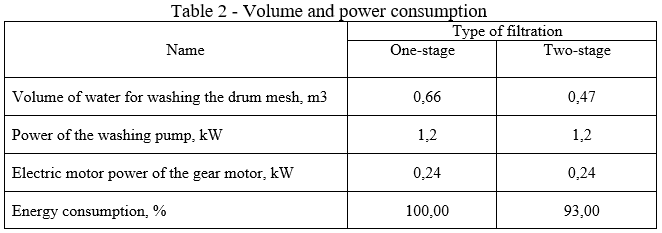

Analysis of the obtained data shows that during the application of a two-stage mechanical drum filter, the amount of water required for washing the cells was 26% less than with a single-stage mechanical drum filter (Table 2).

During the experiment, the multiplicity and level of feeding, as well as the fish biomass, were approximately at the same level. In feeding trout, granulated feed from one manufacturer and one batch was used. The color of the water did not have significant differences.

Analysis of the obtained data shows that during the application of a two-stage mechanical drum filter, the amount of water required for washing the cells was 26% less than with a single-stage mechanical drum filter (Table 2).

At the same time it was noted, there was a smaller number of flushing pump inclusions and, as a result, savings in energy consumption and water discharged into the sewer. It was also noted that during the preventive measures for cleaning the pits and pipelines from plaque, the two-stage mechanical drum filter coped with large contamination in normal mode, and the single-stage mechanical drum filter entered the overflow phase.

The trend towards improvement of the water quality parameters maintained during the entire period of the experiment. At the end of the experiment, we note that the efficiency indicators of a two - stage drum filter compared to a single-stage drum filter are higher in the following parameters:

- increased filtration efficiency during preventive measures;

- the volume of water required for washing the drum filter has decreased by 26 %;

- the level of energy consumption decreased by 7 %;

- the presence of two stages of water purification makes it possible to replace or repair the filter element without stopping the water circulation in the CWSS.

Conclusions. The results of the experiment indicate the feasibility and economic efficiency of using a two-stage mechanical drum filter in the CWSS.

List of references

1. Vasiliev A. A., Britov A. N. Two-stage drum filter for mechanical water purification / utility model patent No. 195933. Application no. 2019138148. Priority of the utility model November 25, 2019.

2. Vasiliev A. A., Khandozhko G. A., Guseva U. A. Recommendations on the use of modern means of control and management of technological processes in fish-breeding installations of closed water supply / Saratov, 2011. 36 p.

3. Zimens U. N., Vasiliev A. A., Akchurina I. V., Poddubnaya I. V., Semykina A. S. Efficiency of using iodized yeast in feeding the Lena sturgeon / Agrarian scientific journal. 2014. No. 10. - Pp. 20-23.

4. Kitaev, I.A., Vasiliev A.A., Gusev Y.A., Mukhametshin S. S. The Efficiency of the use of drugs "Biopeptide and Ferromatic" feeding the Lena sturgeon in recirculation aquaculture systems / Bulletin of Saratov State Agrarian University named under N. I. Vavilov. 2014. No. 7. - Pp. 9-11.

5. Kitaev I.A., Vasiliev A.A., Guseva U.A. Effect of feed additives "Abiopeptide" and "Ferropeptide" on the amino acid composition of the protein of the muscle tissue of the Lena sturgeon when growing in the CWSS / In the collection: current problems of veterinary medicine, food and biotechnology. Materials of the all-Russian scientific and practical conference. 2015. - Pp. 160-164.

6. Kiyashko V.V., Gurkina OA., Vasiliev A. A., Dolgopolova M.N. Approbation of river crayfish cultivation in industrial conditions / Bulletin of Michurinsk state agrarian University. 2016. No. 1. - P. 47-50.

7. Rudnev M. U., Rudneva O. N., Vasiliev A. A. Economic justification for growing Lena sturgeon and producing black caviar using intensive technology / In the collection: Problems and prospects of development of agriculture and rural territories. Collection of articles of the IV International scientific and practical conference. Ministry of agriculture of the Russian Federation, Saratov State Agrarian University named after N. I. Vavilov; editorial Board: I. L. Vorotnikov; V. V. Butyrin. 2015. - Pp. 123-126.

8. Tarasov P. S., Poddubnaya I. V., Vasiliev A. A., Kuznetsov M. Yu. efficiency of using the additive "Abiopeptide with iodine" in feeding the Lena sturgeon when growing in the CWSS / Agrarian scientific journal. 2015. no. 4. - Pp. 41-44.

9. https://u-z-v.ru/barabannyj-filtr

10. http://www.fao.org/home/ru/

The trend towards improvement of the water quality parameters maintained during the entire period of the experiment. At the end of the experiment, we note that the efficiency indicators of a two - stage drum filter compared to a single-stage drum filter are higher in the following parameters:

- increased filtration efficiency during preventive measures;

- the volume of water required for washing the drum filter has decreased by 26 %;

- the level of energy consumption decreased by 7 %;

- the presence of two stages of water purification makes it possible to replace or repair the filter element without stopping the water circulation in the CWSS.

Conclusions. The results of the experiment indicate the feasibility and economic efficiency of using a two-stage mechanical drum filter in the CWSS.

List of references

1. Vasiliev A. A., Britov A. N. Two-stage drum filter for mechanical water purification / utility model patent No. 195933. Application no. 2019138148. Priority of the utility model November 25, 2019.

2. Vasiliev A. A., Khandozhko G. A., Guseva U. A. Recommendations on the use of modern means of control and management of technological processes in fish-breeding installations of closed water supply / Saratov, 2011. 36 p.

3. Zimens U. N., Vasiliev A. A., Akchurina I. V., Poddubnaya I. V., Semykina A. S. Efficiency of using iodized yeast in feeding the Lena sturgeon / Agrarian scientific journal. 2014. No. 10. - Pp. 20-23.

4. Kitaev, I.A., Vasiliev A.A., Gusev Y.A., Mukhametshin S. S. The Efficiency of the use of drugs "Biopeptide and Ferromatic" feeding the Lena sturgeon in recirculation aquaculture systems / Bulletin of Saratov State Agrarian University named under N. I. Vavilov. 2014. No. 7. - Pp. 9-11.

5. Kitaev I.A., Vasiliev A.A., Guseva U.A. Effect of feed additives "Abiopeptide" and "Ferropeptide" on the amino acid composition of the protein of the muscle tissue of the Lena sturgeon when growing in the CWSS / In the collection: current problems of veterinary medicine, food and biotechnology. Materials of the all-Russian scientific and practical conference. 2015. - Pp. 160-164.

6. Kiyashko V.V., Gurkina OA., Vasiliev A. A., Dolgopolova M.N. Approbation of river crayfish cultivation in industrial conditions / Bulletin of Michurinsk state agrarian University. 2016. No. 1. - P. 47-50.

7. Rudnev M. U., Rudneva O. N., Vasiliev A. A. Economic justification for growing Lena sturgeon and producing black caviar using intensive technology / In the collection: Problems and prospects of development of agriculture and rural territories. Collection of articles of the IV International scientific and practical conference. Ministry of agriculture of the Russian Federation, Saratov State Agrarian University named after N. I. Vavilov; editorial Board: I. L. Vorotnikov; V. V. Butyrin. 2015. - Pp. 123-126.

8. Tarasov P. S., Poddubnaya I. V., Vasiliev A. A., Kuznetsov M. Yu. efficiency of using the additive "Abiopeptide with iodine" in feeding the Lena sturgeon when growing in the CWSS / Agrarian scientific journal. 2015. no. 4. - Pp. 41-44.

9. https://u-z-v.ru/barabannyj-filtr

10. http://www.fao.org/home/ru/

Свой бизнес

по разведению ценных пород рыбы в УЗВ

Нажимая на кнопку, вы даете согласие на обработку персональных данных и соглашаетесь c политикой конфиденциальности